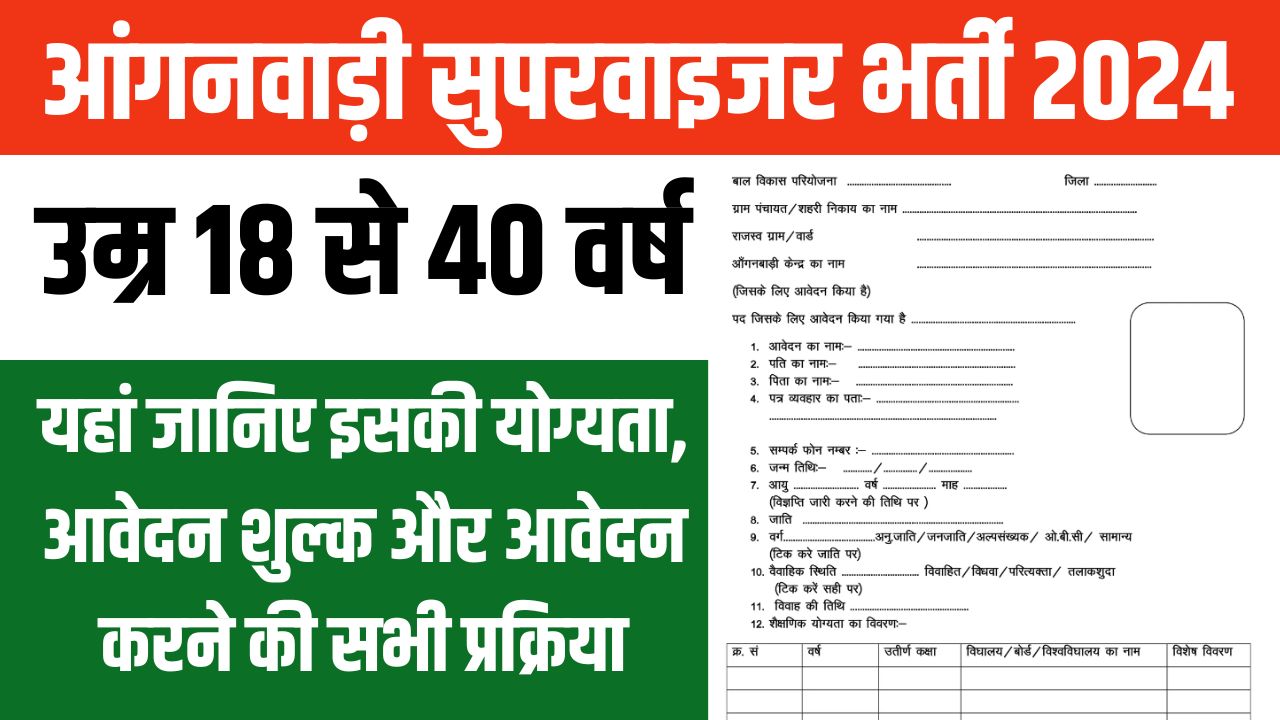

Anganwadi Supervisor Bharti 2024: सुपरवाइजर पद के लिए निकली भर्ती, जानिए योग्यता, आवेदन शुल्क व आवेदन की प्रक्रिया

Anganwadi Supervisor Bharti 2024: भारत में बेरोजगारी एक बड़ी समस्या है, जिससे निपटने के लिए केन्द्र तथा राज्य राज्य सरकार पूरी कोशिश कर रही है। इसी वजह से गवर्नमेंट की तरफ से कई बार नई-नई भर्ती निकाली जाती है। इसी बीच अब आंगनवाड़ी सुपरवाइजर भर्ती के लिए आवदेन की प्रक्रिया शुरू कर दी गई है। … Read more